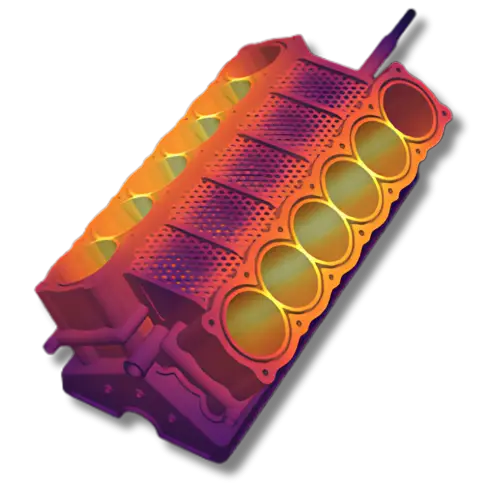

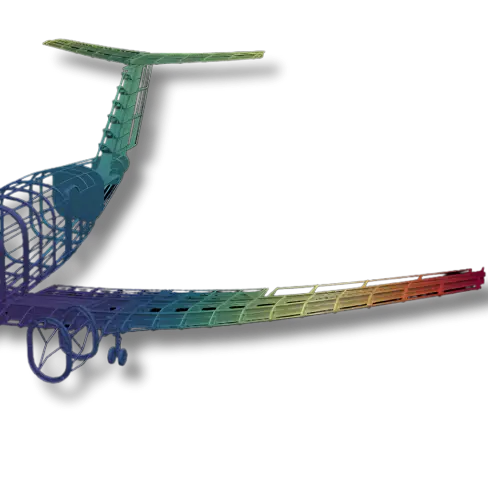

Invented the Immersed Method of Moments™ an automated meshfree FE Technology

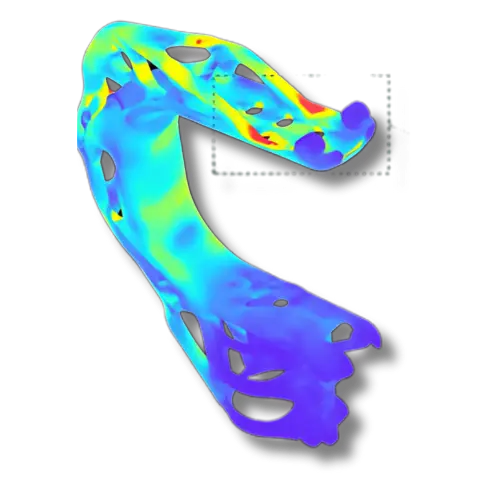

Intact.Simulation is the most flexible mechanical simulation solution in the history of mechanical design.

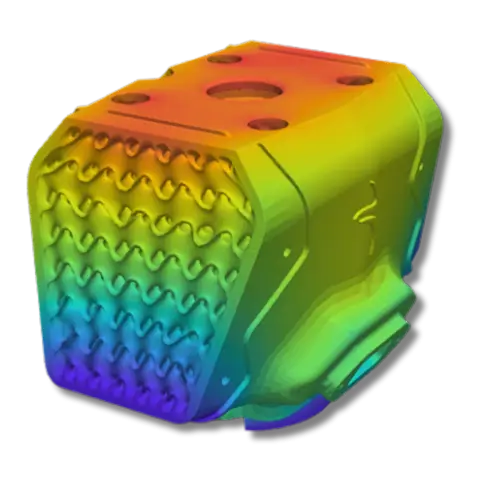

Unlike traditional FEA, which requires manual setup and meshing, Intact’s technology automates processing for any geometry at any resolution, creating reliable finite element models.

It delivers simulation and interoperability at scale—integrating hybrid 3D models, heterogeneous material models, and manufacturing process data into a single streamlined model.

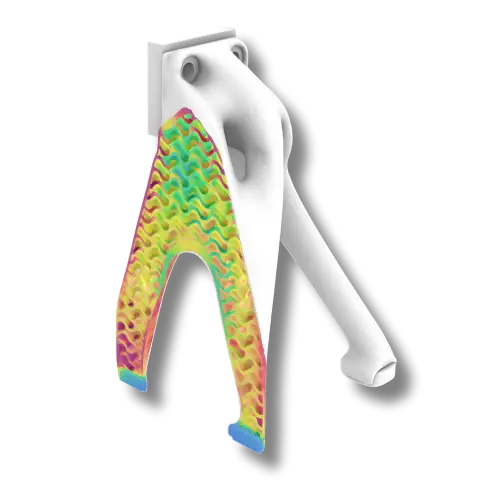

With geometry-based boundary conditions, Intact.Simulation allows easy swapping of models within the same test setup, ensuring performance validation throughout a product’s lifecycle. By providing continuous analytical feedback from concept to production, it enhances product quality and efficiency.

Intact.Simulation was developed with support from the National Science Foundation (NSF), the National Institutes for Standards and Technology (NIST), and the Defense Advanced Research Projects Agency (DARPA).