Customer need

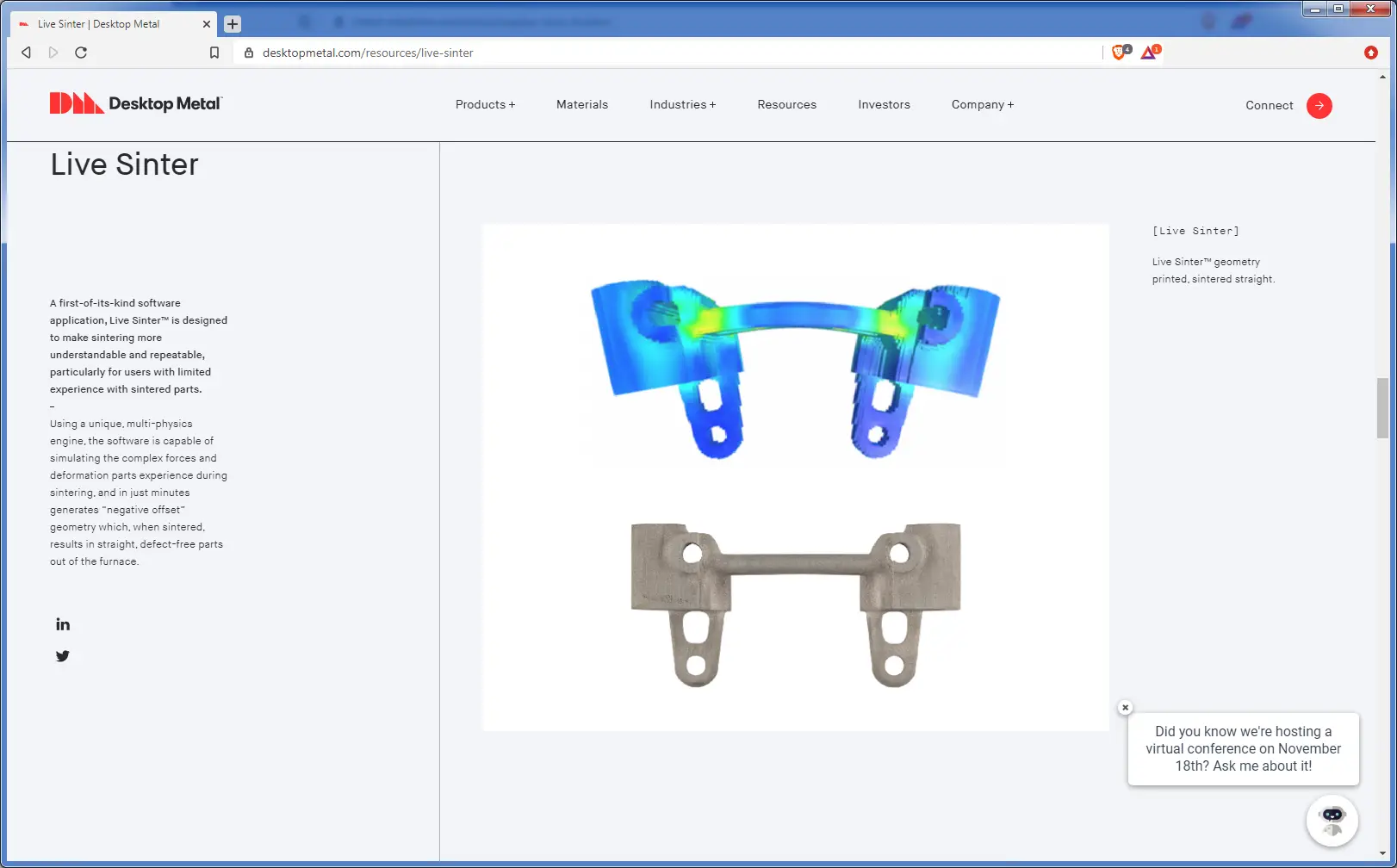

Many powder metallurgy-based manufacturing methods rely on sintering, a process that heats “green” parts comprised of compressed or binder-jet bound metal powders to near-melting temperatures. During the resulting densification, gravity, friction, shrinkage and a multitude of other factors can lead to deformations that produce parts that are consistently dimensionally inaccurate and unusable without additional costly post-processing.

Live Sinter is able to predict the deformations that occur during sintering. but more importantly allows application of a pre-sintering “negative offset” so sintering distortions ultimately result in parts with the desired shape. Central to Live Sinter’s predictive power is integrated stress analysis powered by Intact.Simulation. Intact.Simulation stress analysis takes into account the effects of gravity and friction as parts deform during sintering. It also provides the ability to predict part performance before parts are made.

Demonstrates

- Geometry: voxels and meshes

- Material: isotropic

- Physics: linear static stress

- Deployment: on the cloud using a customized native API

Benefits of Intact Solutions’ plug and play technology for Live Sinter

Challenges addressed

- In-the-loop repeated analyses of changing shape

- Couple analysis with non-traditional physics

- Deployment on the cloud and integrated using API

Additional benefits

- Trivial to query simulation results and inform future iterations