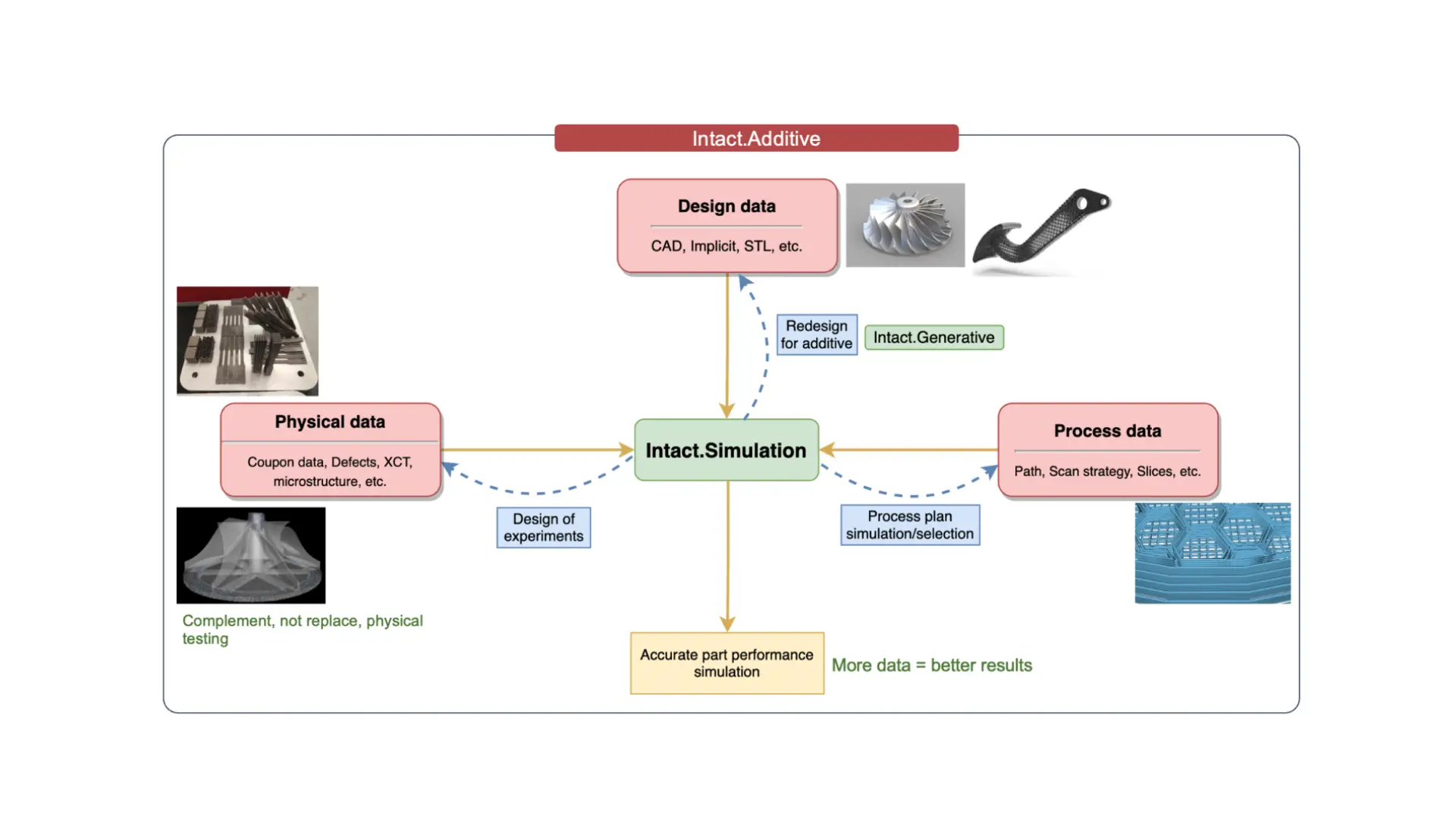

Intact.Additive is poised to deliver the long-sought after solutions to simulation-based verification, validation (V&V) and quality assurance (QA) in additive manufacturing (AM). Finally, you can assess manufacturability and performance of AM materials, structures, components, and processes – in situ, directly on native representations of geometry and materials, be it 3D printed geometries, complex lattice structures, G-code scan patterns, heterogeneous materials, or process induced properties. Intact.Additive offers high-fidelity QA solutions that tightly integrate physical testing with simulation from ground up to leverage both the scalability of simulation and accuracy of physical testing.

Features

- All-in-one simulation platform for standard and customized AM workflows, from process scans to part performance

- Incorporate generative designs, lattices, G-code, slices, CT scans, material tests, and process data

- Handle any complexity (design, process, scale) without meshing, simplification, and other simulation pre-processing bottlenecks

Benefits

- Compare, assess, and validate as-designed, as planned, and as manufactured components

- Handle any complexity (design, process, scale) without meshing, simplification, and other simulation pre-processing bottlenecks

- Eliminate manual simplification and error-prone homogenization assumptions

- Reduce testing through design of experiments that leverages simulation

- Select and optimize AM process plans to guarantee part quality and performance

What can Intact.Additive do for my organization?

In addition to powerful typical workflows in Intact.Additive (see below), partner with Intact Solutions to rapidly develop and deploy custom simulation workflows for your applications. With Intact.Additive, your process physics, models, and data seamlessly fuse together to inform and guide the full spectrum of AM activities, from design and manufacturing to testing and V&V tasks.

Sample workflows that we have developed for our partners

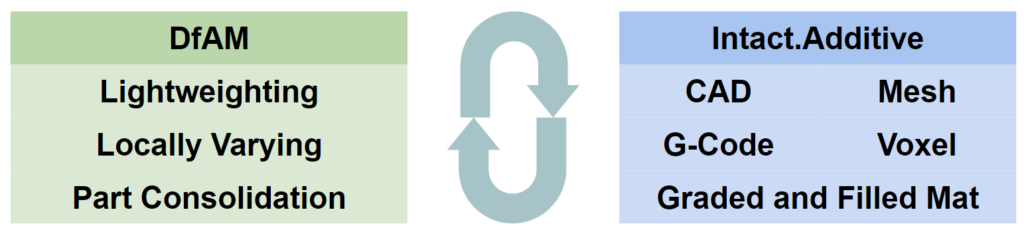

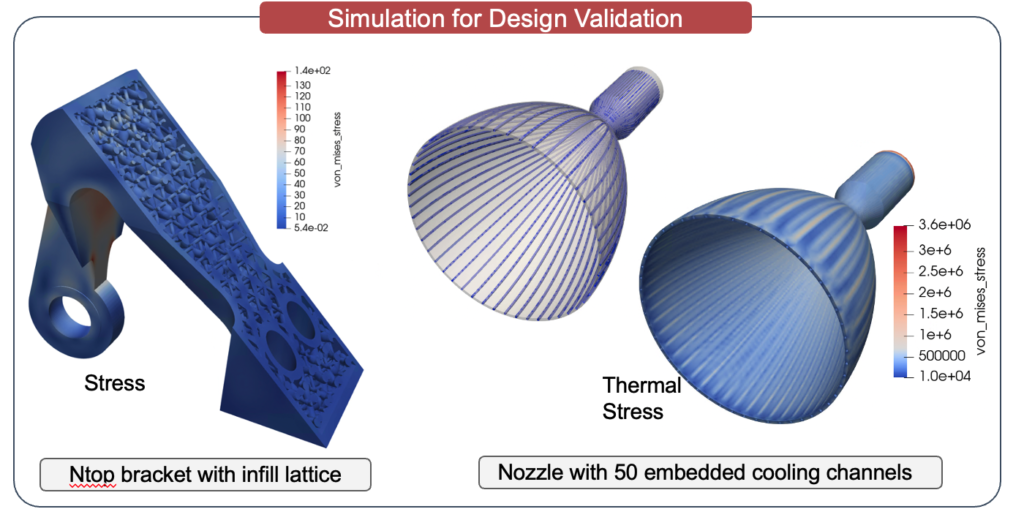

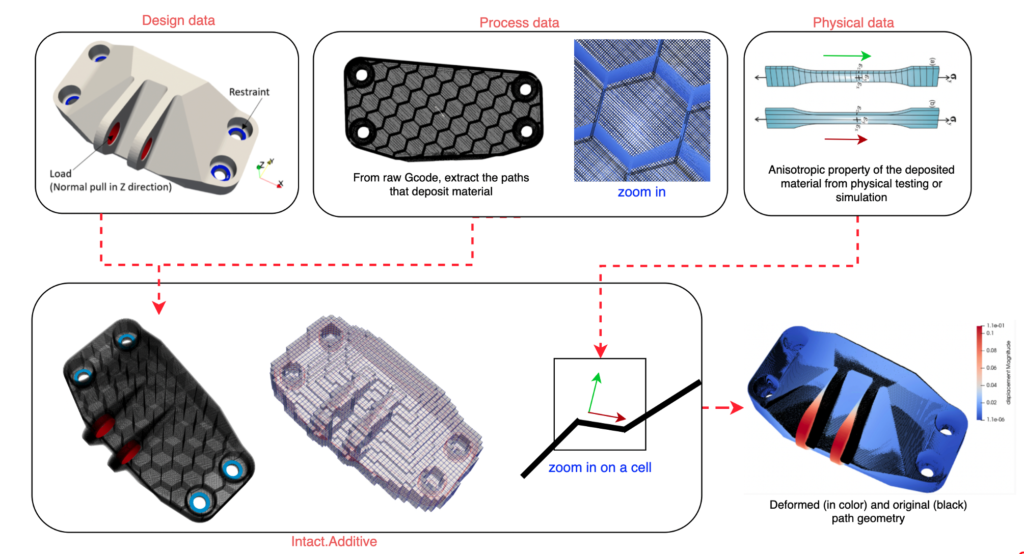

1. Design Validation for DfAM Workflow

DfAM is focused on light-weighting, part consolidation, and printability. But will the generated G-code perform as intended? Intact.Additive can accelerate DfAM by rapidly simulating the performance of the new designs by directly analyzing the native geometry (Brep, Implicit, Voxel, G-code, etc.) without any expensive and manual pre-processing.

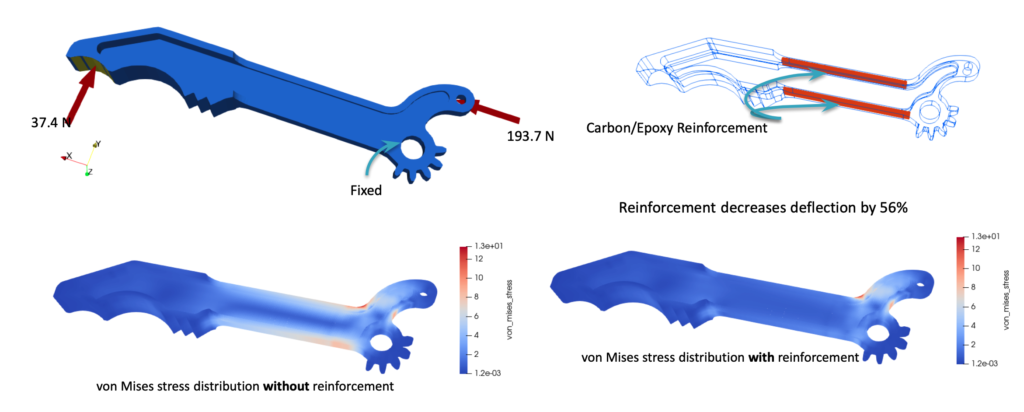

2. Validating Performance of As-manufactured Part

Parts made using additive manufacturing often have anisotropic and spatially varying material properties that depend on the manufacturing features (such as overhang, support structure, etc.) and process plan (including build orientation, scan path, and laser power). With Intact.Additive, as-manufactured models can be accurately simulated in any combination of modeled and measured data, including G-code, lattice models, physical test specimen, process data and CT scans — reducing testing and costly iterations.

This workflow shows analysis on path model (from G-code) of a part made using Fused Deposition Modeling (FDM) where anisotropic properties of the deposited polymer is accounted at the path level.

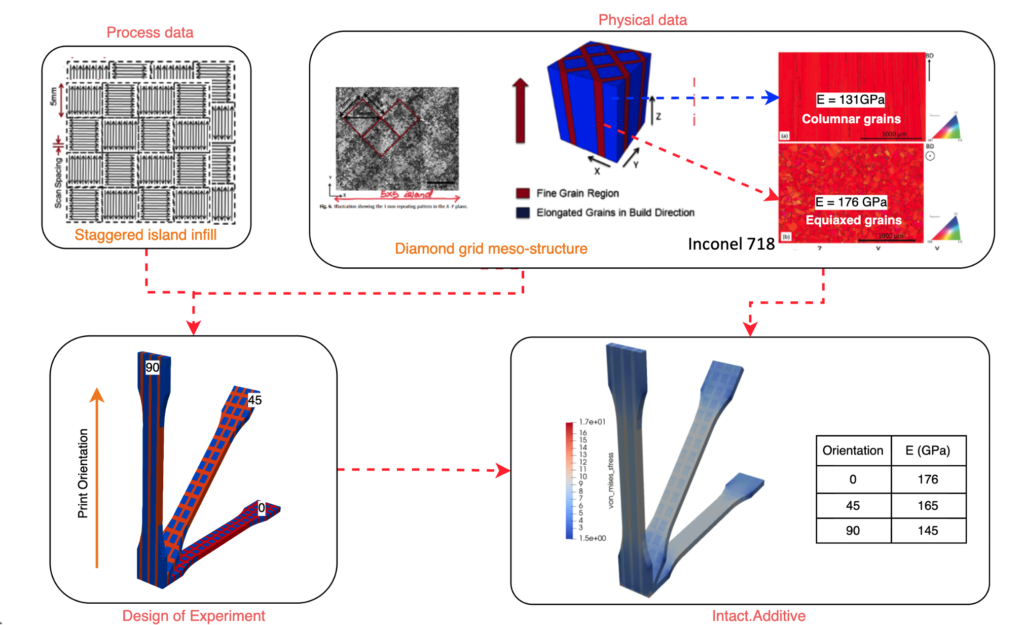

3. Simulation-based Material Characterization

With dozens of process parameters, qualifying AM microstructures and material for different combination of process parameters is both time consuming and expensive. Intact.Additive ushers new era in design of experiments, using only a few physical “basis” tests and leveraging simulation to characterize material for a large range of process plans, thereby speeding material characterization by many folds.

Examples of basis tests (experimental) being used to characterize new combination of process plans using simulation.

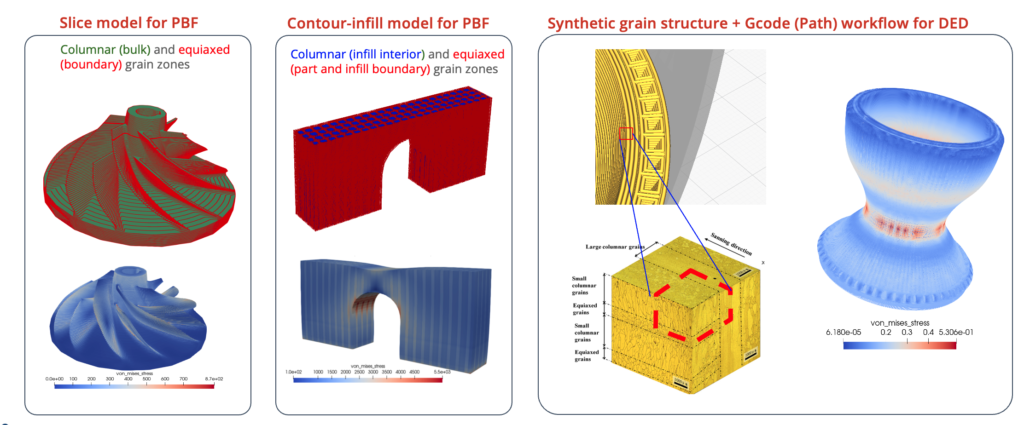

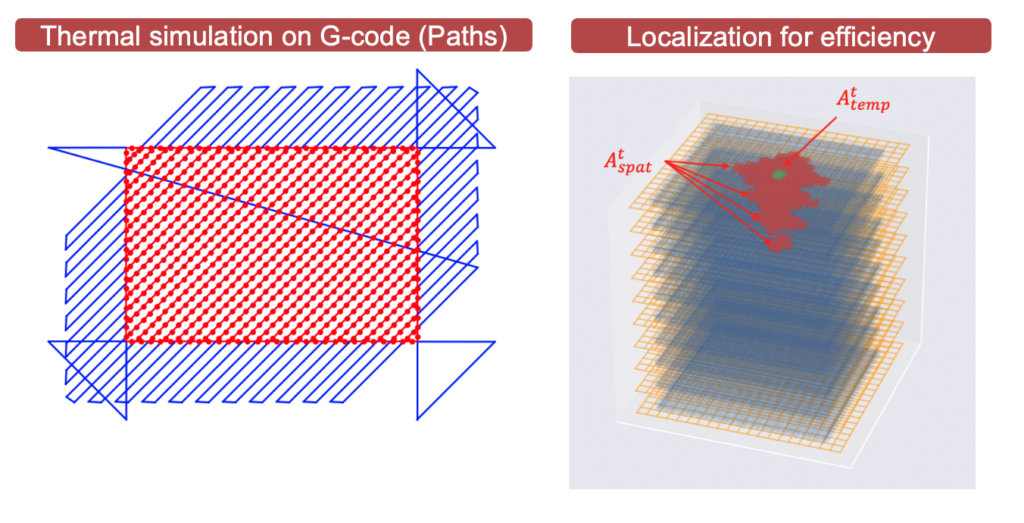

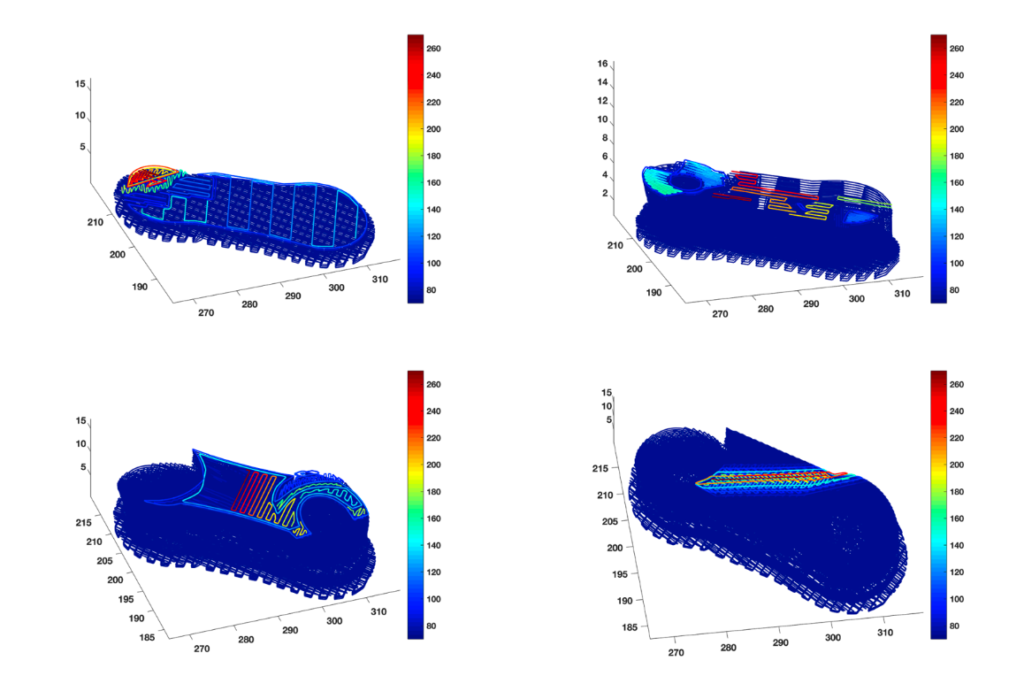

4. Path-scale to Part-Scale Process Simulation

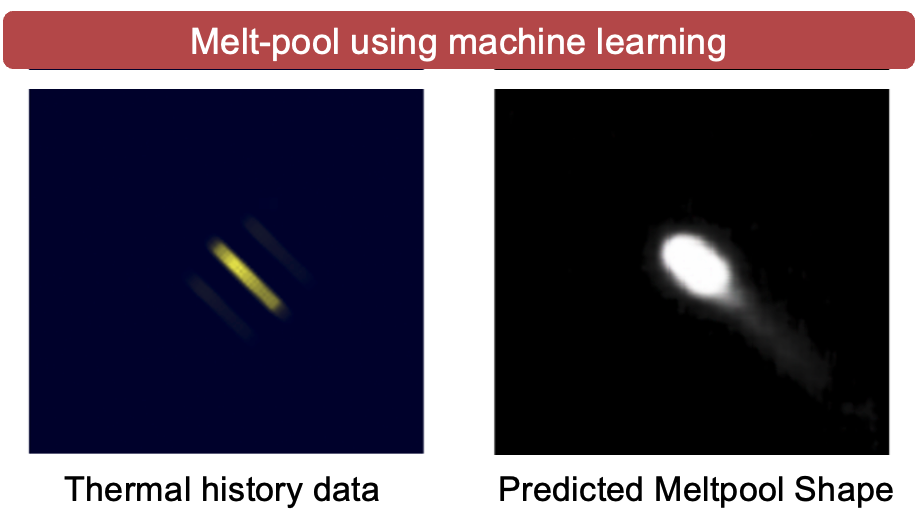

Can you really afford and trust other simulations of AM processes that are cast in terms of voxels, layers, and other simplifying assumptions? With Intact.Additive, process simulation starts at any scale using native geometry and material models, whether it is microstructure, G-code, or measured in-situ data (such as melt-pool images) and scales up to predict performance of features, parts, and assemblies.

Thermal history is used to predict the shape and size of melt-pool.

Part-scale simulation for FDM

Path-scale Simulation of FDM process scales to predict AM part performance.