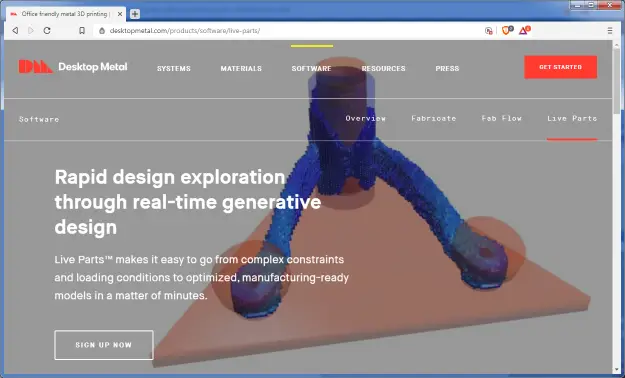

Customer need

Live Parts uses a proprietary hybrid representation of shape that rapidly evolves and updates in time based on a variety of bio/chemical analogies subject to structural constraints and optimality criteria. Meshing is not an option and Desktop Metal did not want to develop a new customized solver.

Demonstrates

- Geometry: voxels and meshes

- Material: isotropic

- Physics: linear static stress

- Deployment: on the cloud using a customized native API

Benefits of Intact Solutions’ plug and play technology for Live Parts

Challenges addressed

- Radically new representation of shape

- In-the-loop analysis of rapidly changing geometry requiring highly efficient analysis

- No time for pre-processing

- Deployment on the cloud and integrated using API

Additional benefits

- Ability to accommodate future changes in shape representation, material, physics, etc.